Submersible Pumps Frequently Asked Questions

- A submersible pump is one which is submerged in water or any other fluid medium.

- These pumps have an electric motor as the prime mover. The water or fluid moves from the bore well or a submerged tank through a series of stages, a stage comprising an impeller and diffuser/bowl, and is pumped out at the ground level or as per the application need.

- The impeller which is mounted on the shaft spins due to the mechanical energy provided by the prime mover. As water gets sucked into the impeller through the eye, it gains kinetic energy from the impeller vanes.

- The water exits the impeller vanes and enters into the diffuser/bowl, where the kinetic energy is converted to pressure (head). The water then moves on to the next impeller and Head (Pressure) of water increases at each stage as described above, until it reaches the delivery casing.

- At the delivery casing the water reaches the end application with the necessary accessories.

The submersible pumps can be classified as radial flow, transition flow or mixed flow based on the specific speed of the pump. In general, the mixed flow is meant for higher discharge, whereas radial flow pump operates at higher head with lower discharge.

An electric submersible is one where is the prime is an electric motor. The electric motor can be of any the following types: AC, DC, Brushless DC, PMSM, SynRM. These can be water cooled or oil cooled.

A bore well submersible pump used for clear water application is a centrifugal pump. Typically, these pumps have multiple stages of impeller and diffuser/bowl to build water pressure (head).

- Submersible pumps are safe to be used in water or fluid medium as the electric motor is sealed.

- The electric cables are generally connected at the ground or surface level wherein the leads are terminated to a control panel/starter.

- At the bottom of the bore well or a tank, any wire / lead connection is sealed inside the motor and the chances of electric failures are highly improbable.

- Considering that the user has chosen the right pump size (outer diameter) that matches the bore well diameter and the application, the pump can be easily installed without any safety issues.

- The motor and pump are also held together by a robust mechanical design and the chance of separation is unlikely.

The choice of a submersible pump depends on the application. Before buying a pump, ensure that the specifications of the pump suits the requirement.

Some of the key requirements that need to be considered while selecting a bore well submersible pump are listed below:

- Size of bore well

- Yield of bore well

- Static water level (below ground level)

- Dynamic water level (below ground level)

- Expected maximum low water level during summer

- Proposed erection depth of the pump set

- Existing /proposed delivery pipe size

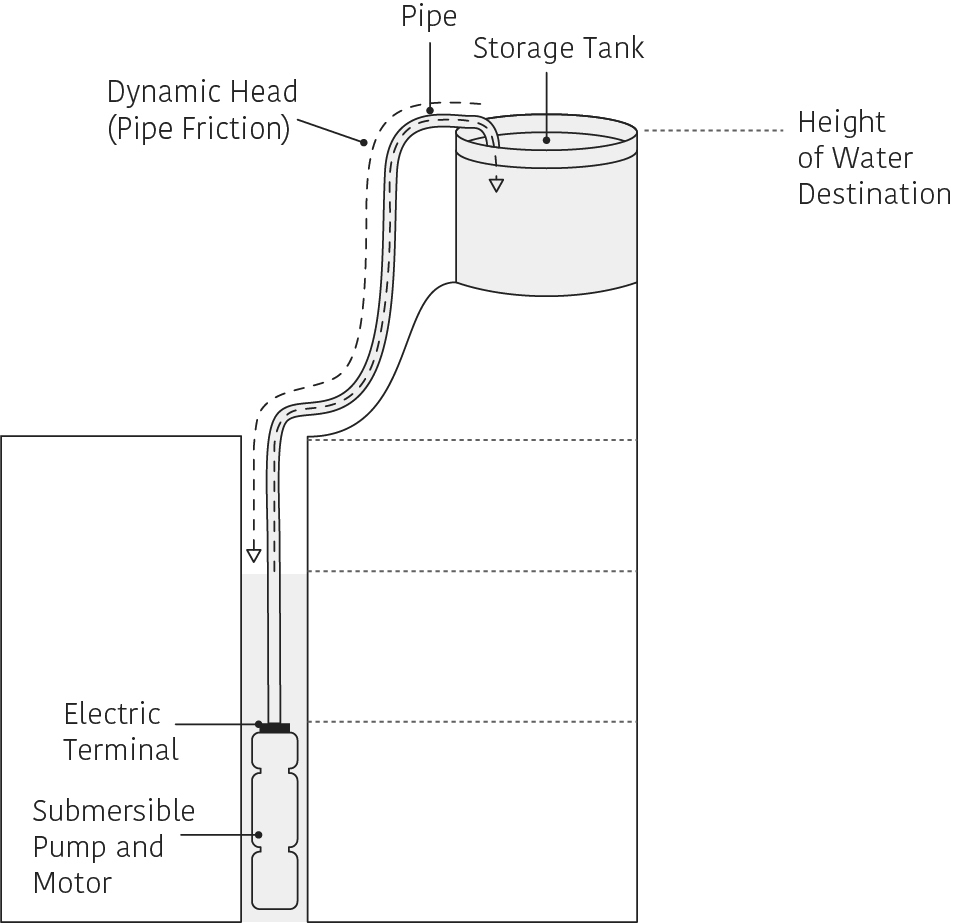

- Vertical elevation from water source to discharge point

- Horizontal distance from bore well to delivery point of the application

- Number of fittings like tees, bends, valves etc.

Key terms to understand specifications/ requirements

- Head – the total head is calculated as below:

Total Head = Suction Head + Delivery Head + Friction Loss + Fitting Losses

- Suction Head – Distance between water surface to pump suction point. Can be considered as zero for a borewell submersible pump

- Delivery Head * – Distance between pump to delivery point of the application

- Friction Loss * – Loss of head due to fluid (water) flow through the pipe.

- Fitting Loss – Loss of head due fittings, like gate valve, check valve, bends etc.

* While calculating the delivery head and friction losses, consider the length of both vertical and horizontal pipe until the delivery point.

- Bore size

- Diameter of the bore well is very important to select the right size of pump

- Delivery pipe size

- Delivery pipe size is the diameter of the pipe at pump outlet

- It is measured in inches or millimeters

- If there is an existing pipeline, the delivery casing of the pump should match the existing pipe size

- If it is a new pipeline, the delivery size will be decided depending on the distance to which the water must be delivered

- Material of construction

- Material of construction should be chosen based on the application of the pump

- Material of construction is important for the reliability of the pump

- Discharge

- The required amount of water at the outlet is called discharge. The discharge is usually around 80% of the total yield of a bore well submersible pump. So, please choose the right kind of pump after evaluating the discharge required.

- A submersible dewatering pump is one that is used for pumping out water/fluid from waste water tanks, rain water pits, mining pits, or from similar sources.

- These pumps allow suspended solid particles to pass though the impeller vanes. However, the particle sizes that the pump can handle will depend on the design of the vanes.

- These pumps are generally open or semi-open impeller. The prime mover is a sealed electric motor.

- A submersible cutter pump is a variation of the dewatering pump, which allows solid particles to pass through the impeller after being shred through a cutter.

Non-clog submersible pumps are ones which have an open or semi-open impeller that allows clogs, rags or suspended particles to be pumped along with the fluid. A cutter is required before the impeller vane to shred the clogs, rags or other suspended particles.

- For clear water applications, the submersible pumps can be used for either bore well or open-well applications

- Bore well submersibles are used to pump water starting from 50 feet below the ground. At present, these pumps are being used for depths upto 1500 feet below the ground. However, as the ground water levels are rapidly decreasing, there are efforts to design the submersible pumps for higher depths. The size of the bore well can be 3”, 4”,5”,6”,7”, 8”.

- Submersible pumps are typically used for residential apartments, commercial complexes, and municipal and industrial water circulation, irrigation systems

- Submersible dewatering and cutter pumps are used for sewage treatment plants, water well and deep well drilling, mine dewatering

Submersible pumps are used for a variety of applications such as

- Drainage

- Sewage pumping

- General industrial pumping

- Slurry pumping

- Residential complexes

- Commercial and municipal, establishments

- Water wells

- Oil wells

- Sewage treatment plants

- Seawater handling

- Firefighting

- Water well and deep well drilling

- Mine dewatering and irrigation systems.

- Easy to install:

Unlike any surface pump sets, a submersible pump installation does not require a foundation.

- Open well submersible is generally suspended in water (fluid) by a rope. The rope is tied to a rigid support above the ground.

- Submersible pump with a delivery pipe is held by supporting clamps that rest on the upper edge of the bore well casing pipe. An expensive pump room at the source location is eliminated.

- A small lid covers the bore well to prevent the contamination of water.

- Priming:

- There is no necessity for priming as the pump is always submerged and water is present inside the pump due to pressure gradient.

- Noiseless operation:

- As compared to a surface pump, the submersible pump generates lesser noise. These pumps also have the advantage of being under the ground.

Yes, submersible pumps have check valves. Check valves permit water flow in only one direction, and are required on all submersible pumps. Some submersible pumps have built-in check valves, and are suitable for operation without an external check valve provided the pump setting is not too deep.

No, priming is not required for submersible pumps. The major advantage to a submersible pump over other options is that it never has to be primed, because it is already submerged in the fluid.

Yes, single stage open well submersible pumps are installed horizontally. Bore well submersible pumps however are installed vertically.

No. If the pump is run dry then its moving parts will become extremely hot, causing severe damage to the pump over time and greatly limiting its service life. For this reason, the float switches should be arranged so that the fill level in the shaft does not fall below the minimum level required to operate the pump.

There are a variety of factors that could cause your submersible pump to run continuously. But regardless of the reason, a submersible pump that runs without stop will burn out more quickly than a submersible pump that runs intermittently.

Your submersible pump may not be working owing to various reasons. Please check the manufacturers troubleshooting guide, consult a trained mechanic or a customer service representative. The troubleshooting guide is available here.

The customer is not advised to open a submersible pump on his own.

Please consult a trained mechanic or a customer service representative of the manufacturer

Check the trouble shooting guide and the maintenance manual before attempting to remove the submersible pump from the bore well.

It is recommended to consult a qualified or a trained mechanic to help remove the submersible pump.

Contact the authorised service centre or a trained mechanic to repair the submersible.

For Taro pumps, click here to get details of our nearest service centre.

Submersible pumps are to be used according to specifications provided by the manufacturer. The pump should be installed at the recommended depth with the necessary accessories as mentioned in the user manual and/or name plate.

Once the pump is installed as per the instructions, the pump can be operated by the starter panel based on the availability of water in the bore well. Ensure that there is a dry run protector connected to the pump so as to avoid any damage to the pump.

Connecting the submersible pump to a power source is mentioned in the instruction manual. However, it is recommended to be done by a trained mechanic.

The customer is not recommended to rewind the motor on his own. It has to be done through a trained mechanic or at authorised service centres.

The winding designs are generally unique to the manufacturer and can vary for pumps from different manufacturers.

For Taro pumps, click here to get details of the nearest service centre to you.

The best quality submersible pumps are designed to suit the application, energy efficient, use high grade of materials for reliability and long life and have an optimum price. The manufacturers of these pumps have accessible service network and good after sales support with warranty.

Submersible pumps are available for sale in the open market through dealers.

Taro pumps can be bought from our authorised dealer. Please click the link to get the nearest Texmo Industries Authorised Dealer or contact our Customer Care through toll free number 1800-102-8888.

Submersible pumps are available for sale in open market through dealers. You can get the product price details from dealers.

Taro pumps price you get from our authorized dealer. Please click the link to get the nearest Texmo Industries Authorised Dealer to know the price of required submersible pump or contact our Customer Care through toll free number 1800-102-8888.